Company Information

Message from the President

Our history brings us a long way back to 1938. We have ever since been supplying a wide range of fiber reinforced plastics (FRP) with light weight, non-corrosion, yet great strength, and excellent durability, and providing valuable solutions to various industries from infrastructure, communications, high-quality architecture to corrosion-resistant plant.

In April 2021, our new history started as part of Nippon Molymer Group, who has vast experiences in supplying plastic materials, parts and products to living life, industrial materials, automotive, electronics, medical and healthcare markets globally, and this transformation has added new dimensions to the values we can offer.

Together with the technical expertise we have built over the years, we will do our utmost to exceed our valued customers’ expectations and would like to grow together for a long time to come.

Toshiyuki Yasuda

President

Corporate Operating Policy

Corporate Vision

We strive to create safe, secure, and comfortable living environments by widening the use of environmentally friendly FRP materials.

Operating Style

As professionals in the field of resin composite materials, we continually evolve to pursue the most advanced technologies and supply the best solutions to customers in various fields.

Improving the Quality of Our Service

Our company executives are responsible for the continued improvement of our service quality, supported by the efforts of our employees.

Continual Improvement in the Quality of Our Service

- We strive to ensure that our value to customers is continually being improved. This involves developing value in new areas and refining our organizational structure.

- One strategy for doing the above is for all workers to be aware of customer satisfaction in their daily duties. This principle permeates and continues to improve our company.

Corporate Aim: To ensure customer satisfaction.

Corporate Policy: To use customer satisfaction as an gauge by which to improve our operations.

- MOLYMER MATEX nurtures our organization’s ability to make refinements in order to better achieve our corporate aim and improve performance. We strive to continuously create and instill a corporate climate that emphasizes excellence.

- To improve our level of service, all staff are trained to be conscious of customer satisfaction. We also strive to create a customer-oriented corporate structure and support organizational modifications for this purpose.

» MOLYMER MATEX embraces reform in order to achieve our corporate vision.

|

|

Company Information

| Company Name | MOLYMER MATEX CO.,LTD. |

| President | Toshiyuki Yasuda |

| Founded | April 15 1938 |

| Capital | 300,000,000 yen |

| Shareholder | Nippon Molymer Co., Ltd |

| Business Area | Fiber Reinforced Plastics (FRP): Development, design, manufacture, sales and construction. Resin Products: Development, design, manufacture, sales and construction. Architectural Lighting Products: Development, design, sales and construction. Glass Products: Sales. |

| Headquarters | 1-26-6 Hashimotodai, Midori-ku, Sagamihara, Kanagawa 252-0132 Japan TEL +81-42-772-1171 FAX +81-42-773-0167 |

|

| Tokyo Office | 3F Sansho Bldg. 3-2-9 Nihombashi, Chuo-ku, Tokyo 103-0027 Japan TEL +81-3-3516-0277 FAX +81-3-3516-0288 |

|

| Osaka Office | 7F Sanko Osaka Hommachi Bldg. 2-3-8 Hommachi, Chuo-ku, Osaka 541-0053 Japan TEL +81-6-6267-0688 FAX +81-6-6267-0689 |

|

Headquarters |

Tokyo Office |

Osaka Office |

| Company name | MOLYMER MATEX (THAILAND) CO.,LTD. Website: https://www.molymermatexthai.com/ |

|

| Head office and Factory |

480 Moo 4, Sukhumvit Road, Phraeksa Subdistrict, Mueang District,Samut Prakan 10280 TEL : +66 (0) 2-323-0774〜6 FAX : +66 (0) 2-323-0777 |

|

Company History

| 1938 | Dainippon Glass Co., Ltd. a corrugated glass manufacturer, was established. Production begins at a plant in Osaka, with a plant in Yokohama established the following year. | |

| 1948 | Asahi Glass Co. Ltd. invests in the company, which it is to become its 100% subsidiary by 1957. | |

| 1955 | Production of corrugated sheets of Glass Fiber Reinforced Plastic (FRP) beings at the Yokohama plant. | |

| 1957 | A plant in Nagoya is established through absorption of the reinforced plastics molding division of the FRP-producing Tokai Special Glass Co., Ltd. | |

| 1959 | Space shortages at the Yokohama and Nagoya plants result in a shift of operations to a new single plant in Sagamihara, Kanagawa Prefecture. Equipment is upgraded, and production capacity expanded for wide-ranging manufacture of FRP products. |  New Plant at Sagamihara |

| 1960 | Sales begin under the product name ARMOLITE | |

| 1964 |

|

Finn Flyer Yachts |

| 1968 | Installation of a 860 ton hydraulic press which, combined with the 1500 ton press installed the following year, make possible the manufacture and marketing of large-scale FRP hydraulic press products. | |

| 1970 | Installation of large filament winding molding equipment for production of corrosion-resistant FRP. | |

| 1973 | Development and installation of a continuous press molding equipment for production of FRP troughs for electrical systems. | |

| 1976 | Manufacture of BMC precision molded product ROSITETM using technology from Rostone Co., USA. | |

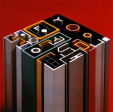

| 1977 | Continuous pultrusion equipment is upgraded for a greater range of PLALLOYTMand the manufacture of large-scale products. |  PLALLOYTM |

| 1979 | Computerized machines are introduced for accounting. | |

| 1984 |

|

FRP Helipad |

| 1987 | Nefcom Co., Ltd. was established for sales of such products as the FRP grating (an alternative to steel grating). | |

| 1989 |

|

|

| 1992 | Company name was changed to Asahi Glass Matex Co., Ltd. as part of an effort to build corporate identity and create a thriving 21st century company. | |

| 1993 | Our NEFTEM material passes the Ministry of Construction’s civil engineering evaluation assessment. | |

| 1994 | Our sensor-integrated FRP Reinforcing Fiber Mesh for Concrete product wins the Industrial Technology Award at CON-EX ’94. |  Steel-Grating Alternative FRP Reinforcing Fiber Mesh for Concrete |

| 1995 | Integrated office was built in factory to promote operational efficiency. | |

| 1996 | Manufacture of optical fibers. | |

| 1999 | All company sites attain ISO9001 certification | |

| 2000 |

|

FRP Pedestrian Bridge |

| 2001 |

|

|

| 2002 | Our industry paper, “Evaluation of the Flexural Properties of Pultruded Square Tubes”, wins the Best Paper Award at CON-EX 2002. | |

| 2003 | Launch of AG1000, a heat resistant sheet used on bridges to house electric cables. | |

| 2005 |

|

HIKARIKABE |

| 2006 |

|

|

| 2007 |

|

|

| 2008 |

|

|

|

Protection Eaves |

|

| 2009 |

|

HIKARI PASAR Louvers |

|

Zounohana (Elephant Trunk) Park, Yokohama Port |

|

|

Kanmon Tunnel |

|

| 2010 |

|

|

| 2011 | Establishment of our Thai subsidiary, AGC Matex (Thailand) Co.,Ltd. as our base of sales and production in the burgeoning Southeast Asia market. | |

| 2013 | AGC Matex (Thailand) Co.,Ltd. extended the second plant. | |

| 2014 | The FRP frame for photovoltaic array receives a Good Design Award. | |

| 2021.4.1 | Became a wholly owned subsidiary of Nippon Molymer Co.,Ltd. | |

| 2021.6.1 | Changed company’s name to MOLYMER MATEX CO.,LTD. | |